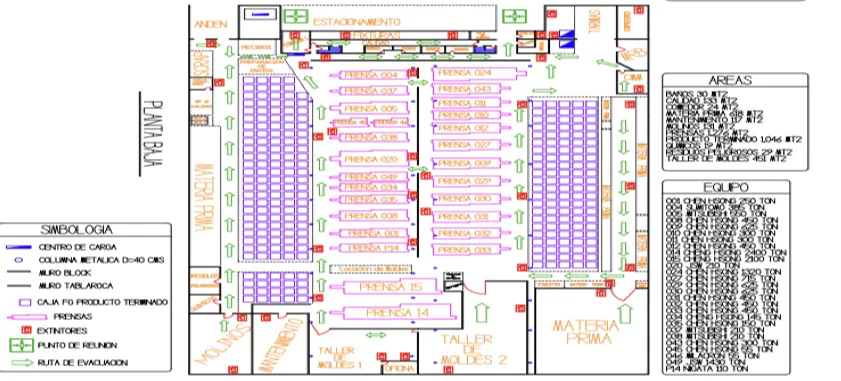

Investor to acquire turn-key

facility for injection molding.

Ease of entry in the

North American market with minimum investment.

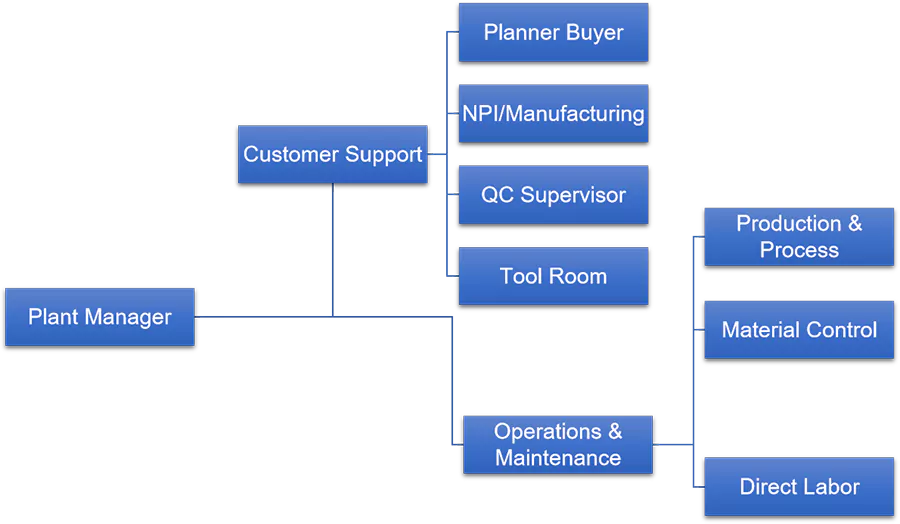

Seasoned Management team and well trained employees.

Strategically located 15 mins

to San Diego, CA border

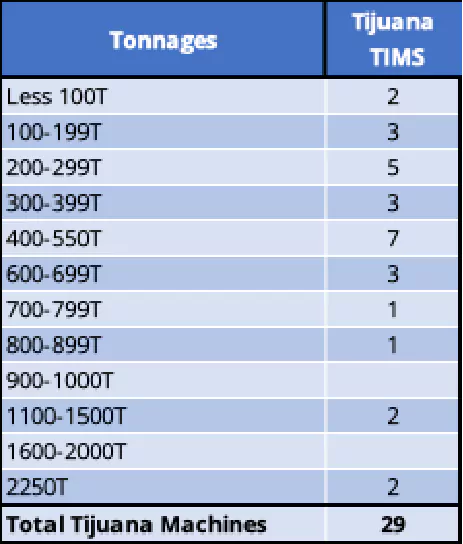

Unique Large Machine Tonnages

of 2400T & 1200 KVA.